PT. Trimaxindo Adimitra

AVEVA Authorized Distributor (formerly wonderware)

PT. Trimaxindo Adimitra

AVEVA Authorized Distributor (formerly wonderware)

AVEVA™ System Platform

(formerly Wonderware System Platform)

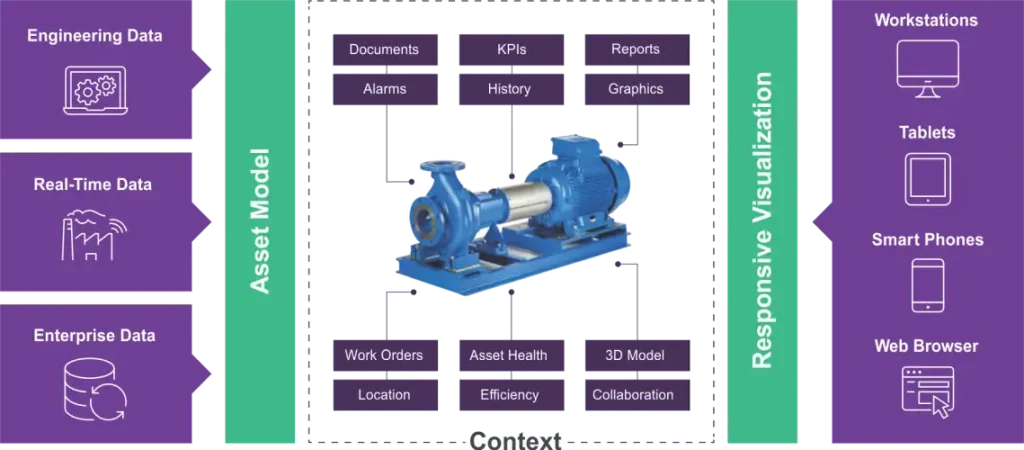

AVEVA System Platform is the world’s only responsive, scalable solution for supervisory, SCADA, HMI, and IIoT applications that integrates the process with the enterprise. System Platform provides a collaborative, standards-based foundation that unifies people, processes, and assets across all facilities for continuous operational improvement and real-time decision support.

Digital Transformation Platform

Connected Operations

- Production Planning

- Scheduling Production

- Execution Remote

- Operations

Unlimited Scalability

- Unlimited Clients

- Unlimited IO

- Unlimited Devices

- Portfolio as Service

Smarter Platform

- Edge to Enterprise

- Analytics

- Connectivity

- Data Management

Centralized Production Platform

Standarize Plant Equipment

Software Redundancy

Object Based Application

Multi User Development

system platform fully integrated add-on modules

System Platform is extremely open and interfaces to countless hardware control and measurement devices and manufacturing systems. It allows extensive re-use of engineering, eases maintenance burdens and extensibility while leveraging the latest IT computing technologies such as virtualization and cloud computing.

aveva system platform

aveva application server

aveva communication driver

aveva historian

aveva system platform client

aveva intouch

aveva operation management interface

aveva historian client

aveva historian webclient

add-on module production &performance application

aveva mes manufacturing execution system

aveva batch management

aveva mobile operator

aveva edge hmi

aveva insight

aveva report

system platform features

With Operations Management Interface (OMI) visualization tools, responsive HMI development abilities, and modern device extensibility, AVEVA System Platform is a powerful operations foundation for any industrial organization.

Built-in Features

Object-based application

Objects represent real world devices such as computers, Motors, Pumps, Valves, etc. It contain of all configuration elements of each piece of your system, such as I/O definitions, logic (scripting), history configuration, alarm/event configuration, security/access control and graphics.

Multi-user development environment

Users are subject to security permissions based on individual system-wide roles. Multiple users can work concurrently on different sets of objects from different ArchestrA IDEs.

Component-based plant application model

The Development Environment utilize an object model of plant to designing an application which models the physical characteristics of the SCADA system, including geographical topology, physical equipment and computer locations.

Leverage the .NET Framework

The ArchestrA technology is an open and extensible system of components based on a distributed, object-oriented design. By leveraging Microsoft .NET and other Microsoft technologies, it provides a productive toolset for building critical operations management software solutions.

Centralized configuration and security

Galaxy Repository is a component to centralized object repository. It components contain :

real time data acquisition, alarm and event management, centralized security, data manipulation, data repository, remote deployment, standarization graphic, security, alarm, historized data, etc.

One global networked namespace

Application Server can be distributed across multiple

computers as part of a single Galaxy Namespace.

Integration

AVEVA Software Product

System Platform contains an integrated set of services and an extensible data model to manage plant control and information management systems.

Controller

Schneider-Electric, OMRON, GE FANUC, AllenBradley , Siemens, Modbus, Profibus, and many others…

Details

Open Architecture

Cloud, IoT, Suitelink, DDE, OPC-UA, MQTT, OPC Server ( KEPWARE, Takebishi, TOP Server etc)

Database

Default : MS SQL Server

Other : Excel, Access , Oracle , MySQL, and many others… (Support OLE DB and ODBC)

PT. Trimaxindo Adimitra

AVEVA Authorized Distributor (formerly wonderware)

Address

Jl. Mangga Dua Dalam Blok H1 No.28-29

Jakarta Pusat - 10730

sales@trimaxindo.com

Phone

(021) 6289977