PT. Trimaxindo Adimitra

AVEVA Authorized Distributor (formerly wonderware)

PT. Trimaxindo Adimitra

AVEVA Authorized Distributor (formerly wonderware)

AVEVA™ MES

( Manufacturing Execution System )

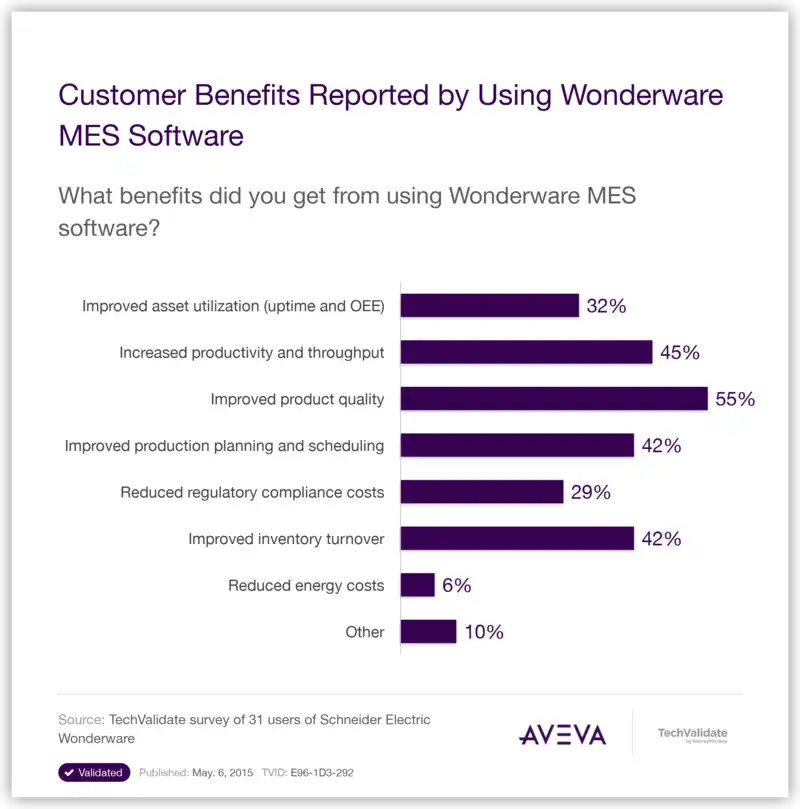

Manufacturing processes are a complex series of steps involving numerous machines, materials, processes and transitions. The execution of these activities requires accuracy, precision and timeliness to ensure profitability and customer satisfaction. By utilizing a digital execution system, organizations can dramatically improve their manufacturing process, revealing efficiency improvements and opportunities to reduce waste.

Manufacturing Operations Transformation

Improved operational performance, optimal regulatory compliance, transparency across your supply chain, and increased plant-to- enterprise interoperability.

Increased Productivity

OEE Improvement

Reduction in Manufacturing Costs

Quality Improvement

More Equipment Uptime

AVEVA MES

capabilities

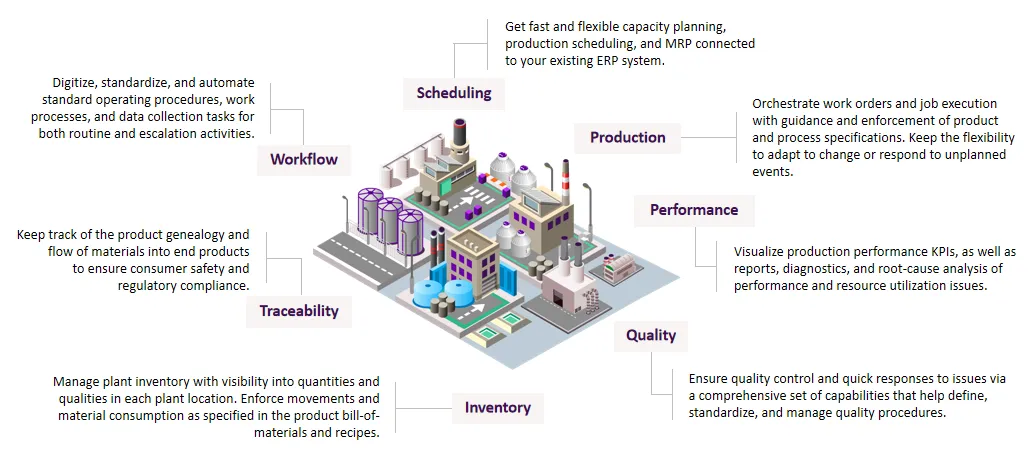

Increase manufacturing flexibility while securing quality and consumer safety by providing product and process guidance

aveva mes Architecture

Enterprise Layer

SAP

ERP

EAM

Enterprise Integration

AVEVA MES

Performance

Operation

Quality

Performance

OEE & Utilization

Production

Order Execution &

Agility / Flexibility

Scheduling

Distribution, Priority, Optimization

Traceability

Materials, WIP,

Tracking & Tracing

Inventory

Received, WIP,

Produced/ Shipped

Quality

BOM / Sampling /

SPC / Compliance

Automation Layer

Real Time Data Platform

[ AVEVA System Platform ]

AVEVA MES components

The AVEVA MES Manufacturing Execution system is comprised of three components that each cover a specific functional area:

Performance

Monitor, analyze and continuously improving operating efficiencies through production and equipment event tracking with work order execution progress information.

- Detect, Capture & View Utilization Events

- Automated & Manual Data Collection

- Real-Time Visibility to Production Performance KPI’s (OEE) for Machines and Lines (OEE)

- Monitor Line Work Order Status and Production Rate

- Indication of Line Bottleneck and Schedule adherence

- Enables Root-Cause Analysis of capacity losses

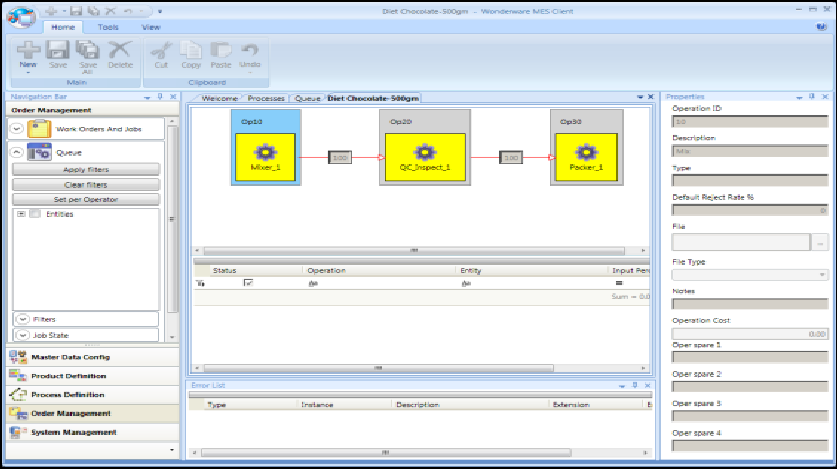

Operations

Digitize and standardize work order execution processes, enforce product build to specification and capture manufacturing execution and material flow information in real time.

- Detect, Capture & View Utilization Events

- Full-Featured MES Capability – “Dock-to-Dock”

- Paperless Work Order and Product Specification Mgmt.

- Real-Time Visibility to Production and Inventory activities

- Business Rules to secure Quality to Specification

- Comprehensive Electronic Manufacturing Genealogy and Material Traceability

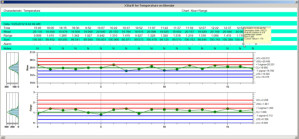

Quality

Automate quality operations and sample plan execution, providing visibility into trends and rule-violation notifications to effectively reduce quality losses, minimize variation and improve yields.

- Dynamic Quality Sample Plan generation based on Work Order Specification (Product and Process)

- Automatic Data Sampling or Manual Sampling Procedure Enforcement based on Work Order Execution Status

- SPC Alerting and Charts to Identify and Correct Quality Deviations in Real-Time

Digital manufacturing execution reduces production costs by increasing throughput,

reducing scrap and rework and providing higher quality products.

Increased transparency in order fulfillment and reduced variance in product quality increases customer satisfaction

while increased responsiveness to unforeseen events or product quarantine/recalls secures brand equity and consumer safety.

Production Management

Digital information and rules management for work order dispatching and tracking for any combination of manual or automated equipment job execution.

Quality Operations

Automate and enforce quality inspection and data collection procedures in alignment with the real-time status of work order and job execution, and in response to shop floor events for reducing giveaway and variance in production results.

Digital Workflow Management

Automate operational activity and data collection processes, eliminating paperwork and manual error-prone procedures.

Track and Trace

Reduce the cost of regulatory compliance and protect brand equity with automatic electronic record keeping for detailed product genealogy and end to end material traceability in minutes.

Inventory Operations Management

Real time tracking of materials, semi-finished and finished products including receiving, transfers or for managing Kanban inventory as materials are consumed and products are made.

Empowerment and Mobility

Empower the modern workforce with a digital and mobile user experience and keep them connected with mission-critical processes on and offline.

Bill of Material and Recipe Management

Quality losses can be minimized and consistency improved through enforcement of product and process specifications.

Plant Performance Management

Unlock more value and capacity from existing assets with visibility into line and plant equipment utilization and Overall Equipment Effectiveness (OEE) KPI’s.

Enterprise Integration

Using AVEVA Enterprise Integration with Enterprise Resource Planning enables agile, short-term production management and provides schedule flexibility and adoption for the plant as well as supply chain visibility into operations and inventory.

PT. Trimaxindo Adimitra

AVEVA Authorized Distributor (formerly wonderware)

Address

Jl. Mangga Dua Dalam Blok H1 No.28-29

Jakarta Pusat - 10730

sales@trimaxindo.com

Phone

(021) 6289977