PT. Trimaxindo Adimitra

AVEVA Authorized Distributor (formerly wonderware)

PT. Trimaxindo Adimitra

AVEVA Authorized Distributor (formerly wonderware)

AVEVA™ Recipe Management

(Formerly Wonderware Recipe Manager Plus)

Simplify recipe optimization, deployment, adaption and execution in manufacturing operations with a commercial off-the-shelf formula and recipe management software. Digital recipe management secures consistency in product quality and increases efficiency through automation of equipment setup processes and recipe execution. The automation system neutral software enables standardization and central management of product formulations for use in multiple production locations and is designed for operational team collaboration to adopt new recipes faster.

Digital formula management and recipe execution

The control system neutral software enables standardization of formula and recipe management across the business and helps speed up new product introduction processes.

Benefits:

- Reduce machine setup and changeover times

- Consistent batch to batch production results

- Improve operational performance and flexibility

- Reduce risks of managing product variation

- Lower cost of compliance with electronic change and execution history, including electronic signatures

- Facilitate standardization to reduce the number of systems used for recipe management in plants today and to improve the new product introduction process

- Fast time to value with rich out of the box functionality

Multi Grade Products

Multi Product, Single Stream

Web-based User Interface

Digital recipe management

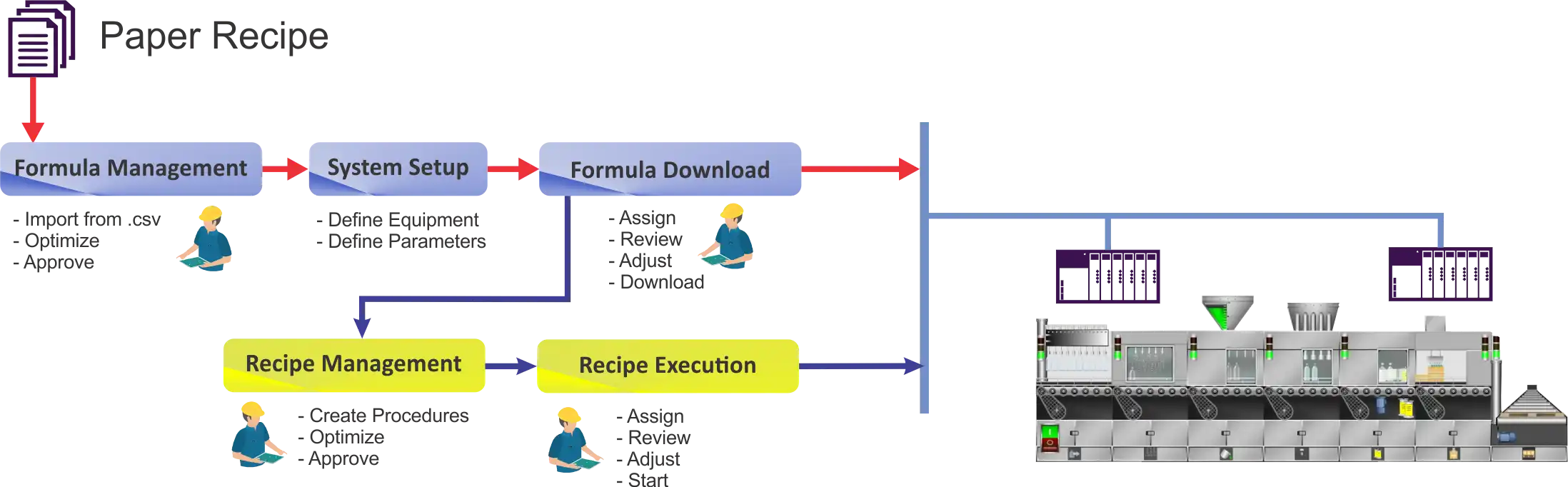

recipe management workflow

recipe management features

Formula Management

Formula Management and Download, enables fast and consistent equipment set up – the key to flexibility for many CPG or Food and Beverages manufacturing processes.

Recipe Management

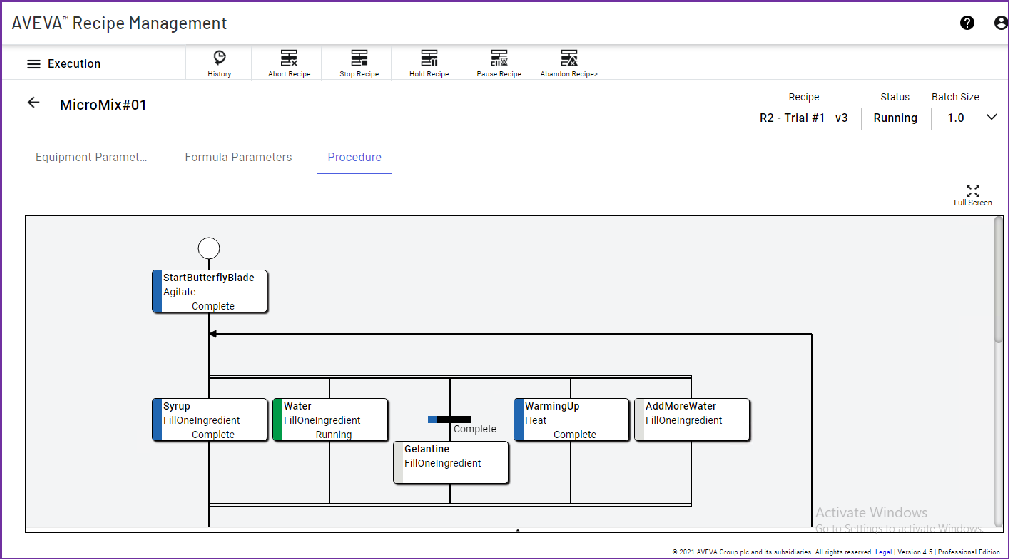

Recipe Management and Execution, provides automation and repeatability of recipe execution on production units, work cells or production lines for batch oriented and hybrid processes.

Execution History Record

Comprehensive history records and reporting allow users to view historical information about formulas and recipes that have been created, changed, or executed. Equipment, formulas, and recipes are all “versioned” items, meaning any configuration change increments the version number.

Integrate with Any Automation System

The software can be integrated with System Platform or used standalone with any control system via the OPC UA Data Access specification. The recipe procedure is coordinated with the control system using a state interface that can be configured to provide full alignment with ISA-88 standards.

recipe management component

AVEVA Recipe Management is designed to simplify the processes related to recipe deployment, optimization

and execution in manufacturing operations and for standardization of recipe management across your business.

Increase your business agility by managing more product variation with reliable consistency and quality, and the ability to take new products to market faster.

Formula Management and Download

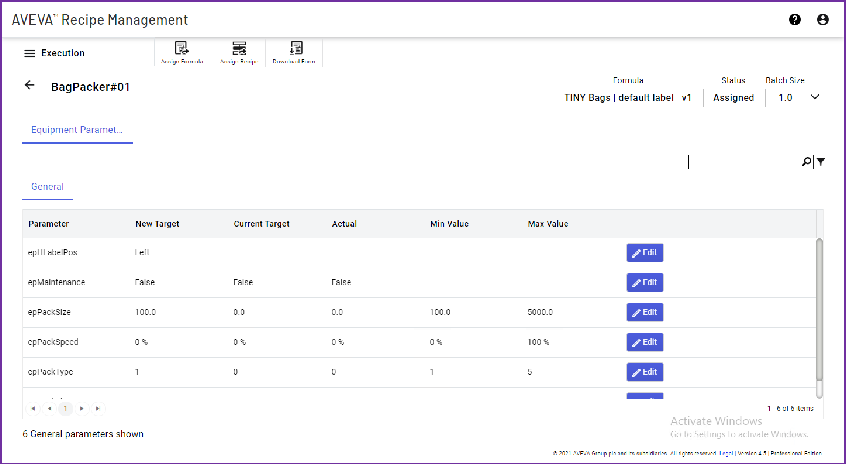

Formulas are defined independent of shop floor equipment, which allows users to centrally manage product definitions for use in multiple production locations regardless of each location’s automation system. Formula download is easy, using the web based user interface.

- Operators assign a formula by browsing and selecting from a list of available and approved formula instances for specific equipment.

- Operators can review the assigned target values, adjust them within given limits, and download the formula to the connected automation system.

Benefit

- Formula parameter management and value transfer for any equipment/system

- Serves many production “Recipe” requirements

- Reduced Machine Setup & Changeover Times

- Consistent production results for process-oriented manufacturing with static procedures

- Improved operational performance and flexibility

Recipe Management and Execution

Recipe management and execution contains the defined procedure and a mapped formula that defines the making of a product by associating a formula and capability parameters. Manual capabilities are available for manual data entry and acknowledgment.

- To execute a recipe an operator simply assigns a recipe to the appropriate equipment and starts, monitors, and controls its execution.

- They can adjust parameter values within the defined limits, either prior to recipe start or even just before the capability is executed.

Benefit

- Procedures for defining the order in which capabilities are executed in a recipe.

- Recipes are built by combining any Formula with any Procedure

- Automates Batch Processes which require procedural steps.

- Reproducible, consistent Processes and Product Quality

- Improved operational performance and flexibility

PT. Trimaxindo Adimitra

AVEVA Authorized Distributor (formerly wonderware)

Address

Jl. Mangga Dua Dalam Blok H1 No.28-29

Jakarta Pusat - 10730

sales@trimaxindo.com

Phone

(021) 6289977