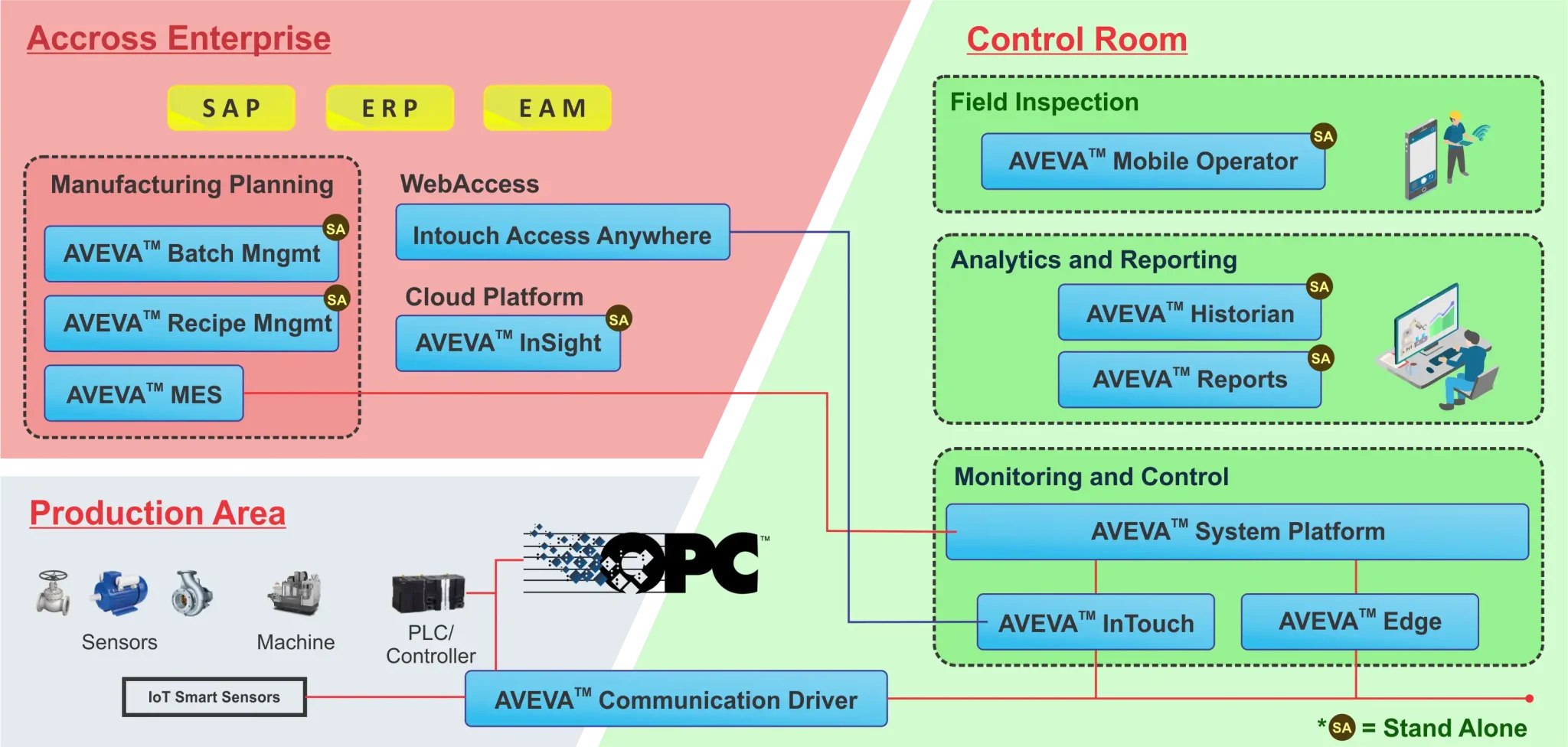

Product ecosystem mapping

aveva product list

- All Product

- Scada HMI

- System Integration

- Data Logging

- Report

- Cloud Platform

- Asset Management

Enterprise Visualization

AVEVA Unified Operation Center

Analytics / Report

Manufacturing

Cloud-based

Cloud Platform

Skills / Training

AVEVA Teamwork

Online Development

AVEVA Integration Studio

Operations Control Platform

SCADA Visualization

Online SCADA

InTouch Access Anywhere

SCADA Web Browser

InTouch Web Client

SCADA Visualization

Communications

Communications

OPC Server

- Takebishi

- TOP Server

- Matrikon

- KEPware

- etc

Asset Equipment

Sensors

IioT Sensors

OPC UA

MQTT

Machine

PLC / DCS

Edge

Perfect solution for frontline teams that require local process monitoring and control at the asset, equipment or line level with IIoT and embedded HMI capabilities.

Area :

– Machine

– Production Line

Supervisory

Ideal for centralized management of distributed SCADA or operations into single unified plant model aimed at driving standardization across departments.

Area :

– Control Room

– Plant/ Site

Enterprise

IT OT convergence platform aimed at driving collaboration and enterprise visibility across regional or global operations.

Area :

– Multi-Site

– HeadQuarter/ Office

Enterprise Visualization

AVEVA Unified Operation Center

AVEVA™ system platform

System Platform is the centralization engine uniting data with context and providing a comprehensive visualization framework featuring re-usable content to create the optimal user experience.

AVEVA™ communication driver

Connect to the widest variety of hardware and software solutions, using a device-agnostic, multi-brand communication strategy.

AVEVA™ reports

(formerly Dream Report)

Capable of collecting and archiving real-time information in databases, generating professional reports on schedule, on event or demand.

Basic

Perfect solution for frontline teams that require local process monitoring and control at the asset, equipment or line level with IIoT and embedded HMI capabilities.

Advanced

Capture and store high-fidelity big data to unlock trapped potential for operational improvements, from single-node to multi-site facility.

Cloud-Plaform

Secure, software-as-a-service (SaaS), for collecting, storing, and visualizing industrial data throughout the organization from anywhere.

– Microsoft SQL Server (Express-10GB)

– Capture High Speed Data

– Data Compression (5-year storage)

– Integration Across Platform

– KPI/OEE Analytics

– Predictive Analytics

– Access anywhere, anytime

Data Logging

Cloud Platform

AVEVA™ reports

(formerly Dream Report)

Capable of collecting and archiving real-time information in databases, generating professional reports on schedule, on event or demand.

AVEVA™ insight

(formerly Historian InSight)

Secure, software-as-a-service (SaaS), for collecting, storing, and visualizing industrial data throughout the organization from anywhere.

AVEVA™ mes

(Manufacturing Execution System)

Digital manufacturing execution enables standardization of operational processes, and reduces production costs by increasing throughput, reducing scrap and providing higher quality products.

AVEVA™ mobile operator round

(formerly Wonderware InTelatrac)

Equip field workers with the information they need to make tough decisions on the spot, like procedures, equipment diagrams and operating history to improve availability, productivity, safety and compliance.

AVEVA™ batch management

(formerly Wonderware InBatch)

Batch Management software helps manufacturers to improve yields through increased product quality and operational efficiency.

- All Product

- Scada HMI

- System Integration

- Data Logging

- Report

- Cloud Platform

- Asset Management

Enterprise Visualization

AVEVA Unified Operation Center

Analytics / Report

Manufacturing

Cloud-based

Cloud Platform

Skills / Training

AVEVA Teamwork

Online Development

AVEVA Integration Studio

Operations Control Platform

SCADA Visualization

Online SCADA

InTouch Access Anywhere

SCADA Web Browser

InTouch Web Client

SCADA Visualization

Communications

Communications

OPC Server

- Takebishi

- TOP Server

- Matrikon

- KEPware

- etc

Asset Equipment

Sensors

IioT Sensors

OPC UA

MQTT

Machine

PLC / DCS

Edge

Perfect solution for frontline teams that require local process monitoring and control at the asset, equipment or line level with IIoT and embedded HMI capabilities.

Area :

– Machine

– Production Line

Supervisory

Ideal for centralized management of distributed SCADA or operations into single unified plant model aimed at driving standardization across departments.

Area :

– Control Room

– Plant/ Site

Enterprise

IT OT convergence platform aimed at driving collaboration and enterprise visibility across regional or global operations.

Area :

– Multi-Site

– HeadQuarter/ Office

Enterprise Visualization

AVEVA Unified Operation Center

AVEVA™ system platform

System Platform is the centralization engine uniting data with context and providing a comprehensive visualization framework featuring re-usable content to create the optimal user experience.

AVEVA™ communication driver

Connect to the widest variety of hardware and software solutions, using a device-agnostic, multi-brand communication strategy.

AVEVA™ reports

(formerly Dream Report)

Capable of collecting and archiving real-time information in databases, generating professional reports on schedule, on event or demand.

Basic

Perfect solution for frontline teams that require local process monitoring and control at the asset, equipment or line level with IIoT and embedded HMI capabilities.

Advanced

Capture and store high-fidelity big data to unlock trapped potential for operational improvements, from single-node to multi-site facility.

Cloud-Plaform

Secure, software-as-a-service (SaaS), for collecting, storing, and visualizing industrial data throughout the organization from anywhere.

– Microsoft SQL Server (Express-10GB)

– Capture High Speed Data

– Data Compression (5-year storage)

– Integration Across Platform

– KPI/OEE Analytics

– Predictive Analytics

– Access anywhere, anytime

Data Logging

Cloud Platform

AVEVA™ reports

(formerly Dream Report)

Capable of collecting and archiving real-time information in databases, generating professional reports on schedule, on event or demand.

AVEVA™ insight

(formerly Historian InSight)

Secure, software-as-a-service (SaaS), for collecting, storing, and visualizing industrial data throughout the organization from anywhere.

AVEVA™ mes

(Manufacturing Execution System)

Digital manufacturing execution enables standardization of operational processes, and reduces production costs by increasing throughput, reducing scrap and providing higher quality products.

AVEVA™ mobile operator round

(formerly Wonderware InTelatrac)

Equip field workers with the information they need to make tough decisions on the spot, like procedures, equipment diagrams and operating history to improve availability, productivity, safety and compliance.

AVEVA™ batch management

(formerly Wonderware InBatch)

Batch Management software helps manufacturers to improve yields through increased product quality and operational efficiency.